By Joshua I. France, Riegl USA (www.rieglusa.com), Orlando, Fla., and Craig Glennie, University of Houston (www.uh.edu), Houston, Texas.

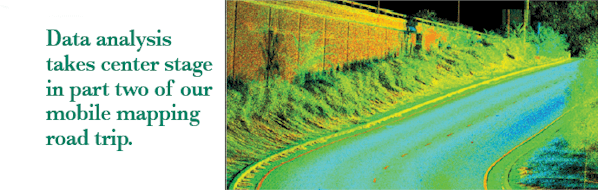

A detailed in the last issue of Earth Imaging Journal, a recent mobile mapping project was motivated by a highway paving company's need for better data so it could manage its costs and bidding approach more effectively. Upon completing data collection for the project along a nine-mile, two-lane section of Florida's Interstate 95, we were confident the processed data would provide complete road surface information for the site.

Now our journey on the waveform continues, as we venture into the software portion of the mobile mapping system and into the point cloud itself. The trip begins with data transfer, a step that separates the acquisition computer from the processing functions and software. Such separation allows for better data management and for the acquisition staff to collect the next project.

Now our journey on the waveform continues, as we venture into the software portion of the mobile mapping system and into the point cloud itself. The trip begins with data transfer, a step that separates the acquisition computer from the processing functions and software. Such separation allows for better data management and for the acquisition staff to collect the next project.

System Specifics

Processing the light detection and ranging (LiDAR) data with the project's mobile scanning system, the Riegl VMX-250, differs from processing airborne LiDAR data or other systems' LiDAR data. The VMX-250's two VQ-250 laser scanners use an advanced signal processing technology called online waveform processing. The technology enables full waveform analysis and rigorous multitarget detection to occur during data acquisition. A single Riegl VQ-250 can process 300,000 laser shots with multitarget capability in terms of range and amplitude measurements in one second. Online processing allows for the data to be quickly georeferenced”in Riegl's RiProcess software suite”by simply unpacking the data from a compressed file format and assigning real-world coordinates based on the selected coordinate system.

It took 1 hour and 12 minutes to collect 18 miles of data on a single Quad-Core computer with a solid-state drive running eight tasks in parallel for processing to a raw point cloud. This workflow included decompression from the raw data format and then georeferencing and projecting the data into the desired coordinate system, processing the trajectory separately using Applanix's POSPac Mobile Mapping Suite. The 18-mile stretch of highway provided excellent Global Navigation Satellite System conditions, with only a few interruptions to satellite lock. This made for a quick, easy trajectory processing experience. Once the data were processed, we assessed the data's quality”first to themselves and second to the survey control points. These quality control checks happen before the data leave the RiProcess software suite.

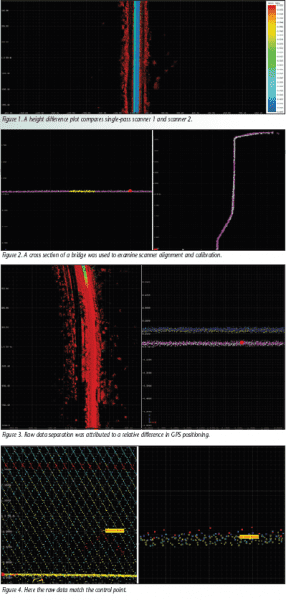

The analysis process entails visually inspecting the data by first examining the system's calibration. Because the Riegl VMX-250 is calibrated by the factory and the scanners are fixed in place on the measurement unit, the alignment of the scanners doesn't drift, but it should be checked as part of any quality control process. Figure 1 gives a vertical difference between the data from the two scanners in a single pass and shows that the vertical alignment of scanner one and two are within 0.02 feet, which is indicated by the blue-teal color. An area's cross section, shown in Figure 2, also can provide additional analysis of the alignment's quality.

An analysis of the highlighted (yellow) section of the bridge deck, shown at the left side of Figure 2, includes 3,260 points”an area 2.5 feet by 8 feet”and has a planar standard deviation of 0.016932 feet in the vertical direction. The barrier wall of the bridge provided a visual confirmation of the horizontal alignment. With 3,556 points, the right side of Figure 2 shows a standard deviation of 0.025065 feet. This quick analysis gives us confidence that the relative alignment of the scanners is stable and no further adjustment needs to be performed. This brings us to examining the relative accuracy of two separate passes.

An analysis of the highlighted (yellow) section of the bridge deck, shown at the left side of Figure 2, includes 3,260 points”an area 2.5 feet by 8 feet”and has a planar standard deviation of 0.016932 feet in the vertical direction. The barrier wall of the bridge provided a visual confirmation of the horizontal alignment. With 3,556 points, the right side of Figure 2 shows a standard deviation of 0.025065 feet. This quick analysis gives us confidence that the relative alignment of the scanners is stable and no further adjustment needs to be performed. This brings us to examining the relative accuracy of two separate passes.

Dual-Pass Analysis

Again, we use a visual assessment to examine the height differences between the two passes. Because of the accuracy of the Global Positioning System (GPS), the height offset between two passes can drift from 0 to 4 inches of separation. As shown in Figure 3, the relative accuracy drifts to a 1.2-inch gap between the two passes. The LiDAR control target shows up clearly in the data as seen from the top in reflectance view, Figure 4, where the control chevron is seen in red. Reflectance is a calibrated intensity product of the system that allows for materials to have the same value whether 5 feet or 50 feet away from the scanner. Now we need to resolve the GPS-induced variations in the data to deliver a consistent surface.

Closing the Gap

At this point in the workflow processing, it's clear that the two scanners on the Riegl VMX-250 are well aligned; however, the multiple passes need adjustment to bring parts of the mission path into a closer alignment”probably due to limitations in the accuracy of the differential GPS solution. The goal is to reduce any vertical offset between passes so the data are merged into a single cloud. Although the vertical relative alignment of multiple paths are within the GPS accuracy estimate of 2 inches, semi-automated extraction programs have a hard time determining where the ground lies when the point cloud is separated by even these small vertical differences.

Riegl Laser Measurement Systems has developed scan alignment tools to close relative data gaps based on observations in the LiDAR data and trajectory quality information. Such tools allow users to quickly analyze and correct data. By delivering high-quality data to third-party software packages for feature extraction, the whole process from collection to data delivery is smoother, more efficient and able to take full advantage of automated classification, segmentation and object extraction routines.

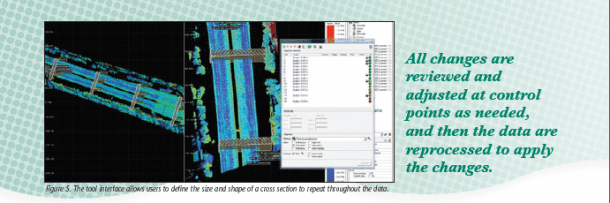

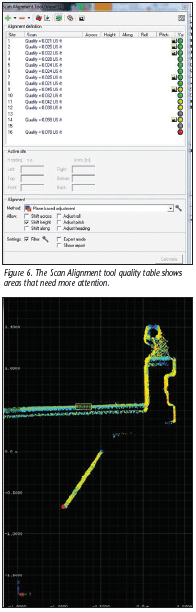

The first step in scan alignment is to make cross sections for each control point section by making a single section and cloning it over the distance between control points, as shown in Figure 5. Some adjustment is required to trim out areas along the road that aren't of primary concern, such as underpasses and vegetation. Once complete, an initial relative alignment calculation can be run for each control point site. Then each area is assigned a quality indicator, and areas with a yellow or red indicator require more attention, as shown in Figure 6.

The first step in scan alignment is to make cross sections for each control point section by making a single section and cloning it over the distance between control points, as shown in Figure 5. Some adjustment is required to trim out areas along the road that aren't of primary concern, such as underpasses and vegetation. Once complete, an initial relative alignment calculation can be run for each control point site. Then each area is assigned a quality indicator, and areas with a yellow or red indicator require more attention, as shown in Figure 6.

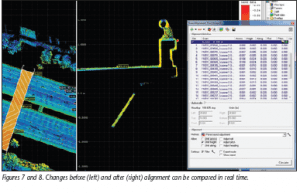

Each area can be selected for refinement based on a couple of parameters and filter options, and an absolute alignment can be performed at each control point. Shifts can be made to the height and across positions for alignment. Typically the height is adjusted first, and an across shift is applied during refinement. The maximum plane separation distance, plane definition point variation and search radius can be adjusted to fit the user's needs. The changes before (Figure 7) and after (Figure 8) alignment can be compared in real time to help the user visualize how the point cloud has been adjusted.

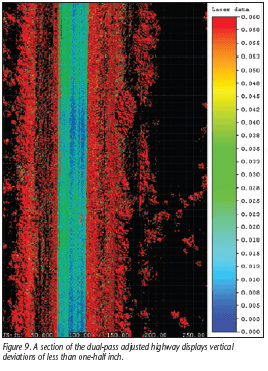

All changes are reviewed and adjusted at control points as needed, and then the data are reprocessed to apply the changes. The resulting point cloud now can be inspected between control points for any misalignment pockets. Using the scan alignment tool, quick work is made of closing the gap to mitigate trajectory-induced errors in terms of weighted averaging of statistically independent measurements, as well as adjusting the data to the accuracy of the absolute control. Some additional work to smooth out other parts of the data between control points may also be done the same way. Now the resulting point cloud is within the combined noise level of the laser sensors and independent ground control. In typical surveys, the point cloud shows vertical deviations of less than a half inch, as seen in Figure 9.

All changes are reviewed and adjusted at control points as needed, and then the data are reprocessed to apply the changes. The resulting point cloud now can be inspected between control points for any misalignment pockets. Using the scan alignment tool, quick work is made of closing the gap to mitigate trajectory-induced errors in terms of weighted averaging of statistically independent measurements, as well as adjusting the data to the accuracy of the absolute control. Some additional work to smooth out other parts of the data between control points may also be done the same way. Now the resulting point cloud is within the combined noise level of the laser sensors and independent ground control. In typical surveys, the point cloud shows vertical deviations of less than a half inch, as seen in Figure 9.

End of the Processing Highway

The road of quality control analysis comes to an end just before the many off-ramps leading to feature extraction software. The final few feet of the road are for data export, which is done with ease thanks to the simple export user interface in RiProcess. In most cases the user simply selects a file location and stores the point cloud in the ubiquitous LAS LiDAR data file format (www.liblas.org). In the next issue of Earth Imaging Journal, we'll arrive at our destination with a look at some of the feature extraction tools and uses of the Riegl VMX-250 mobile data.